AMD 已獲得一項專利 ( 12080632 ),該專利涵蓋玻璃核心基板技術。未來幾年,玻璃基板將取代多芯片處理器的傳統有機基板。這項專利不僅意味著 AMD 已廣泛研究了相關技術,還將使該公司未來能夠使用玻璃基板,而不必擔心專利流氓或競爭對手起訴它。

AMD has been granted a patent (12080632) that covers glass core substrate tech. Glass substrates will replace traditional organic substrates for multi-chiplet processors in the coming years. The patent not only means AMD has worked on appropriate technologies extensively but will enable the company to use glass substrates in the future without risks that a patent troll or competitors could sue it.

圖源:英特爾

包括英特爾?和?三星在內的大多數芯片制造商?都在探索未來處理器的玻璃基板。盡管 AMD 不再生產自己的芯片,而是將其外包給臺積電,但它仍然擁有硅片和芯片生產研發業務,因為該公司根據合作伙伴提供的工藝技術定制產品。

Most chipmakers, including Intel and Samsung, are exploring glass substrates for future processors. Although AMD no longer produces its own chips, instead subcontracting them out to TSMC, it still has silicon and chip production research and development operations as the company customizes process technologies offered by its partners to build its products.

玻璃基板由硼硅酸鹽、石英和熔融石英等材料制成,與傳統有機材料相比,它們具有顯著的優勢,因為它們具有出色的平整度、尺寸穩定性以及優異的熱穩定性和機械穩定性。優異的平整度和尺寸穩定性可以改善先進系統級封裝中超密集互連的光刻聚焦,而優異的熱穩定性和機械穩定性使它們在數據中心處理器等高溫、重型應用中更加可靠。

Glass substrates are made from materials like borosilicate, quartz, and fused silica, which provide notable benefits compared to traditional organic materials as they feature exceptional flatness, dimensional stability, and superior thermal and mechanical stability. Superior flatness and dimensional stability can improve lithography focus for ultra-dense interconnects in advanced system-in-packages, whereas superior thermal and mechanical stability makes them more reliable for high-temperature, heavy-duty applications like data center processors.

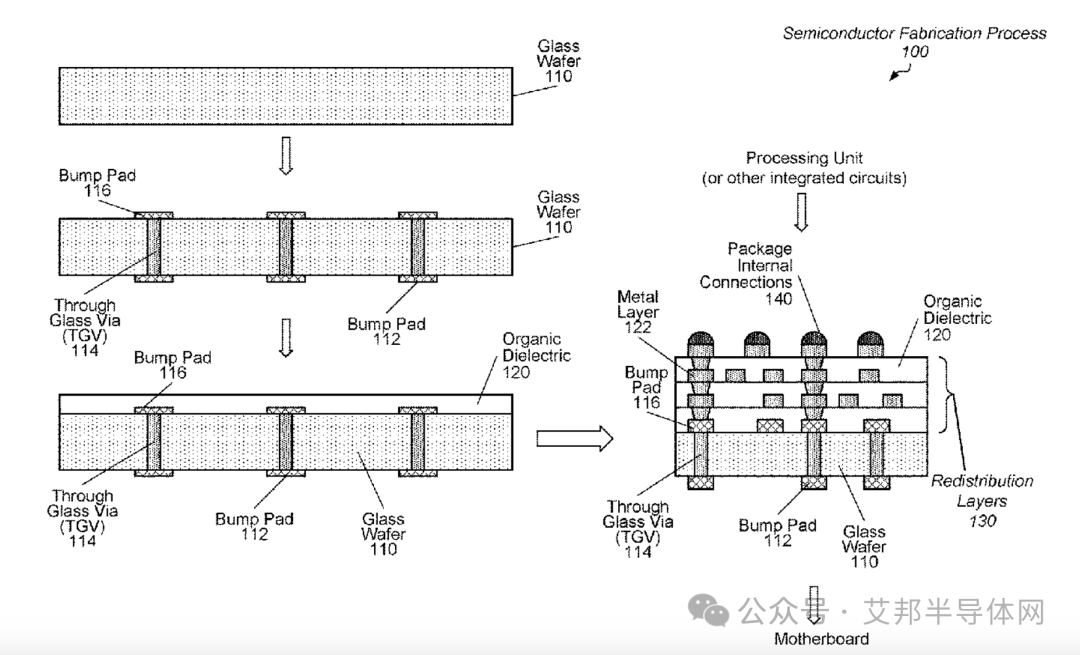

根據 AMD 的專利,使用玻璃基板時面臨的挑戰之一是實施玻璃通孔 (TGV)。TGV 是在玻璃芯內創建的垂直通道,用于傳輸數據信號和電力。激光鉆孔、濕法蝕刻和磁性自組裝等技術可用于制作這些通孔,但目前,激光鉆孔和磁性自組裝是相當新穎的技術。

One of the challenges when working with glass substrates is the implementation of Through Glass Vias (TGVs), according to the AMD patent. TGVs are vertical pathways created within the glass core to transmit data signals and power. Techniques such as laser drilling, wet etching, and magnetic self-assembly are utilized to produce these vias, but for now, laser drilling and magnetic self-assembly are fairly novel technologies.

再分布層(RDL)是先進芯片封裝的另一個組成部分,它使用高密度互連在芯片和外部組件之間路由信號和電源。與主玻璃芯基板不同,RDL將繼續使用有機介電材料和銅;只是這一次它們將構建在玻璃晶片的一側,需要一種新的生產方法。

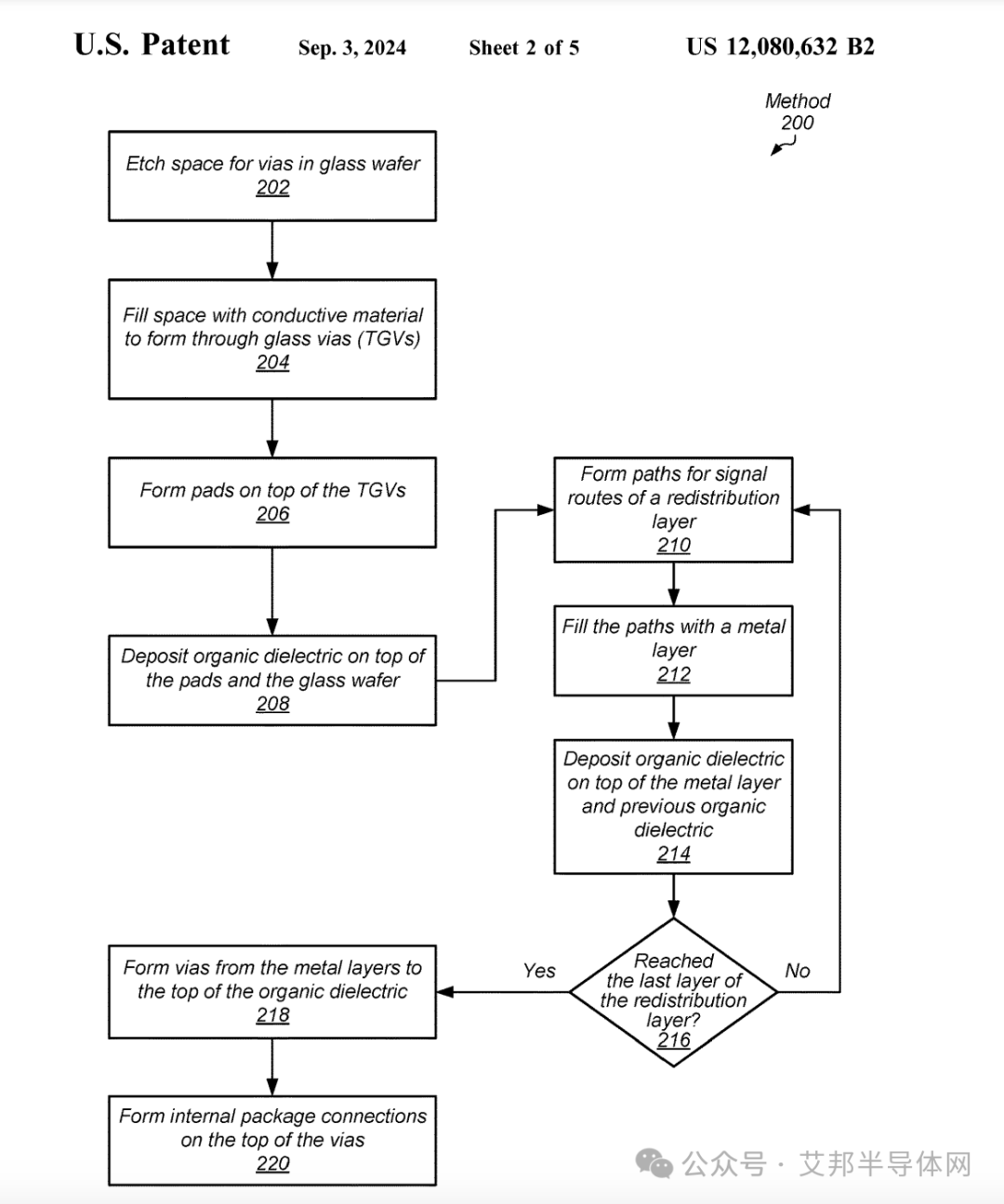

這是一個詳細的玻璃晶圓通孔(TGVs)制造過程,下面是每個步驟的翻譯:

1.? 在玻璃晶圓中蝕刻通孔空間

Etch space for vias in glass wafer.

2.? 填充導電材料以形成通孔玻璃基板(TGVs)

Fill space with conductive material to form through glass vias (TGVs).

3.? 在TGVs頂部形成焊盤

Form pads on top of the TGVs.

4.? 在焊盤和玻璃晶圓頂部沉積有機介電材料

Deposit organic dielectric on top of the pads and the glass wafer.

5.? 形成重分布層的信號路徑

Form paths for signal routes of a redistribution layer.

6.? 用金屬層填充路徑

Fill the paths with a metal layer.

7.? 在金屬層和先前的有機介電層上沉積有機介電材料

Deposit organic dielectric on top of the metal layer and previous organic dielectric.

8.? 從金屬層形成通孔至有機介電層頂部

Form vias from the metal layers to the top of the organic dielectric.

9.? 在通孔頂部形成內部封裝連接

Form internal package connections on the top of the vias.

以上是整個工藝流程的詳細步驟翻譯,涵蓋了從開始蝕刻玻璃晶圓到形成內部連接的完整過程。

Redistribution layers — which route signals and power between the chip and external components using high-density interconnections — are another integral component of advanced chip packages. Unlike main glass core substrates, these will continue to use organic dielectric materials and copper; only this time will they be constructed on one side of the glass wafer, requiring a new production method.

該專利還描述了一種使用銅基鍵合(而不是傳統的焊料凸塊)來鍵合多個玻璃基板的方法,以確保牢固、無間隙的連接。這種方法提高了可靠性,并且無需使用底部填充材料,因此適合堆疊多個基板。

The patent also describes a method for bonding multiple glass substrates using copper-based bonding (instead of traditional solder bumps) to ensure strong, gap-free connections. This approach enhances reliability and eliminates the need for underfill materials, making it suitable for stacking multiple substrates.

雖然AMD的專利中明確指出玻璃基板具有更好的熱管理、機械強度和改進的信號路由能力等優點,這對于數據中心處理器來說是一個優勢,但該專利暗示玻璃基板可以應用于各種需要高密度互連的應用,包括數據中心、移動設備、計算系統,甚至先進的傳感器,這似乎有點過頭。

While AMD's patents clearly state that glass substrates offer such benefits as better thermal management, mechanical strength, and improved signal routing capabilities, which are advantages for data center processors, the patent implies that glass substrates could be applied to a variety of applications requiring high-density interconnections, including data center, mobile devices, computing systems, and even advanced sensors, which seems a bit overkill.

來源:Tom's Hardware

歡迎加入艾邦TGV玻璃基板產業鏈交流群,索取專利原文。誠邀您加入“玻璃基板與TGV技術交流群”,與行業精英共同探討玻璃基板及TGV技術的前沿動態,共享資源,交流經驗。在這里,您可以第一時間獲取技術革新信息,深入解析行業趨勢,與行業領袖面對面交流,共同推動技術革新,探索無限商機。

活動推薦:

主要議題(包含但不限于):

| 1.玻璃基板封裝技術的最新進展與未來展望 |

| 2.TGV 玻璃關鍵技術面臨的挑戰及其解決策略 |

| 3.玻璃襯底材料與先進封裝 |

| 4.玻璃襯底材料的本構模型、破壞機理及其在工程中的應用 |

| 5.先進封裝產業升級中玻璃基互連技術的作用 |

| 6.玻璃基板生產的可靠性探討 |

| 7.最新一代 TGV 玻璃通孔技術助力先進封裝 |

| 8.激光系統在 TGV 中應用及發展 |

| 9.PLASMA 技術在 TGV 加工中應用 |

| 10.面板級玻璃基板的激光誘導蝕刻 & AOI |

| 11.飛秒激光助力先進封裝玻璃基板發展 |

| 12.顯微鏡在半導體先進封裝缺陷檢測中的應用 |

| 13.TGV 填孔電鍍配方及工藝 |

| 14.印刷銅漿與電鍍銅優劣分析 |

| 15.PVD 技術在玻璃基板先進封裝制程應用 |

| 16.在玻璃基板上開發濕化學銅金屬化工藝 |

| 17.異構封裝中金屬化互聯面臨的挑戰 |

| 18.高效RDL制造技術:賦能多種互聯結構的面板級封裝 |

| 19.TGV金屬線路制作的工藝難點及技術解決路徑 |

| 20.玻璃基板介電層材料研究 |

報名方式一:加微信

李小姐:18124643204(同微信)

郵箱:lirongrong@aibang.com

掃碼添加微信,咨詢展會詳情

注意:每位參會者均需要提供信息

或者復制網址到瀏覽器后,微信注冊報名

https://www.aibang360.com/m/100235?ref=100042

原文始發于微信公眾號(艾邦半導體網):AMD 獲得玻璃基板 TGV專利